One of the many benefits of choosing powder coating is the wide variety of finishes available to the customer. Colours, textures, special finishes and technologies; there really is a world of possibilities out there! In this blog, we’ll give you some more details on just a handful of the options available…

Solid Colours

There are of a course a huge variety of solid colours available for powder coating. The most commonly specified of these are the RAL and BS ranges and as such, these form the backbone of our standard stock range, with 100s of colour choices available. From daffodil yellow to spruce green, horizon blue to carnival red and everything in between.

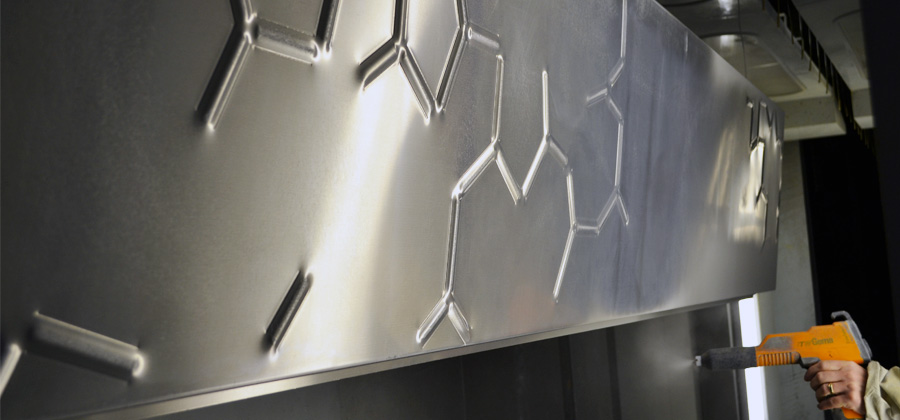

Metallics

Many of our suppliers have a range of metallic colours alongside their standard range, including a new range from Axalta that stands out with its brightness and optical depth. Gold, bronze and precious metal effect finishes are always gaining in popularity, whilst grey never goes out of style when it comes to architectural design.

Textures

A textured finish in powder coating creates great tactility in the final product. They are perfect for coating rougher materials such as galvanised steel, covering any imperfections and giving a smoothing appearance. Textures are most often used in the coating of furniture, lighting and shop fittings.

Anti-Microbial

The development of anti-microbial coatings is an incredible advancement that allows for the safe and hygienic coating of items such as medical products and food processing equipment. Anti-microbial coatings make use of the natural bactericide qualities of silver and have been successfully tested against bacteria such as MRSA, E Coli and Salmonella.

Anodic

The latest development in powder coating technology, anodic coatings take metallic finishes to the next level. It is a great alternative to traditional anodised aluminium, with a superior finish and lesser environmental impact. Anodic coatings are also a fantastic cost effective option for customers, as they can be guaranteed for up to 40 years.