At C&O Powder Coatings, we’ve built our reputation on delivering consistently high-quality finishes our customers can rely on. With over 40 years of experience, we’ve led the way in adopting new technologies that enhance powder coating performance, and it’s one of the reasons customers continue to choose us.

One of the most important decisions we made came over 12 years ago.

We made the decision, long before many others in the industry, to eliminate hexavalent chromium from our pre-treatment process. At the time, it was still widely used across the industry, but we recognised that emerging alternatives were safer, far more environmentally responsible and able to deliver the same performance.

Traditionally, hexavalent chromium was used in powder coating pre-treatment to promote adhesion and enhance corrosion resistance.

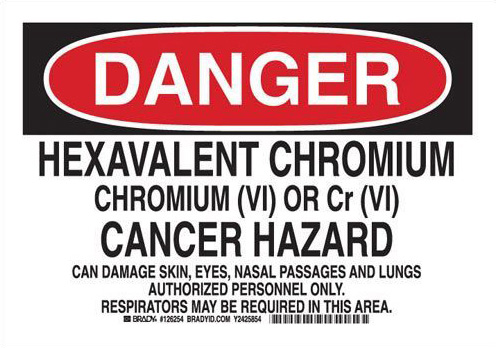

Hexavalent Chromium – The Risks

As a pre-treatment, Hexavalent Chromium is very effective but it comes with significant disadvantages:

- Health Risks

The compound is a known carcinogen and is especially harmful when inhaled and could also cause respiratory problems. - Environmental Damage

Hexavalent chromium is highly toxic in the environment especially to aquatic life and can persist in soil and groundwater for a long time. This makes chemical disposal complex, and without strict handling, potentially harmful to the local environment. - Regulations

The use of dangerous chemicals requires strict regulations. In addition to mandatory PPE, companies often have to manage complex air filtration systems and comply with strict hazardous waste regulations. - Customer Demand

Today, customers expect coatings to meet higher environmental standards. By using a chrome-free pre-treatment and recycling unused powder, we demonstrate our sustainability credentials and help customers meet their own environmental goals.

The New Standard in Pre Treatment

Twelve years ago, there was no legal requirement to stop using hexavalent chromium but we knew that there were much safer and sustainable alternatives.

Today we use Oxsilan. A safer, smarter alternative that eliminates the risks associated with its predecessor while maintaining the quality and standards our customers expect.

Chrome-free alternatives give us:

- Outstanding corrosion resistance

- Excellent adhesion

- No hazardous waste

- A safer environment for our team

Qualicoat and Qualicoat Seaside Accreditations

Our chrome-free pre-treatment achieves both Qualicoat and Qualicoat seaside accreditations, offering a more robust process for atmospheres containing corrosive salts and other aggressive pollutants.

Why Chrome free matters to our customers

Whether you’re in construction, engineering, or architectural design, the quality of your finish matters, but so does the integrity of the process behind it.

By investing in safer, smarter pre-treatment processes, we’re not only protecting our team and the environment, we’re ensuring that every finish we apply stands the test of time.

If you want to know more about how our pre-treatment process helps your coatings last longer and perform better contact our team to find out more.